|

| November 06, 2012 | Volume 08 Issue 41 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Resin selection: Check the data sheet

By Gus Breiland, Customer Service Engineer Manager, Proto Labs

Whether you realize it or not, when you design a molded plastic part you are working at two levels. On the macro level you are creating a shape -- simple or complex -- that meets a variety of needs. At the same time, you are designing at the molecular level by your choice of resin or resin blend. Some aspects of a part's performance are determined primarily by shape. Others, such as strength, are influenced by both shape and material. And still others, like lubricity, are determined by material alone.

With thousands of resins and blends to choose from, material selection can seem daunting. Fortunately, there are some excellent resources that can help simplify the process. General information on a handful of the most commonly used resins can be found on our Protomold design guidelines page. But for more detailed information on literally tens of thousands of resins, the go-to source is the Prospector Plastic Materials Database at IDES. Here, at no charge (after free registration) you can find detailed data sheets on most of the world's resins (see Figure 1). Data is provided to UL IDES by material manufacturers and updated weekly. You can register and create a personal Prospector account by going to www.ides.com/protomold.

Figure 1: Screen shot of materials data sheet from Prospector Plastic Materials Database at IDES.

Let's start by reviewing this sample data sheet for a clear Polycarbonate material, Makrolon-2458. It begins with a general description of the resin and its application, in this case medical devices. The feature list includes characteristics needed for medical application including biocompatibility and sterilizability. This particular resin is also characterized by good mold release, which could be critical for a part in which draft must be minimized, but may affect your ability to paint or plate the part. The agency ratings and RoHS compliance concerning environmental and safety regulations are also available on each form. And appearance, of course, relates to cosmetic issues.

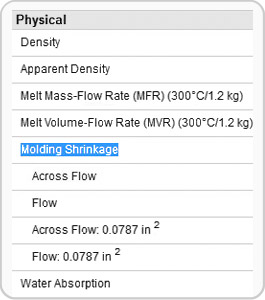

The remainder of the data sheet provides detailed information on the resin's physical, mechanical, thermal, and other characteristics. These may all be relevant to the performance of your finished parts, but one in particular could be important if you plan to compare prototypes in more than one resin. Molding shrinkage (see Figure 2) helps Proto Labs determine how much to adjust the mold size so that cooled, molded parts will match your model. If you plan to test multiple resins, you may want to choose resins with similar shrinkage ratings to ensure that the parts made from different resin in the same mold cool to similar sizes. ABS and polycarbonate, for example, typically have similar shrink rates, while those of ABS and nylon are very different. When shrink rates are different, consider the order in which you have them molded; reduce your cost by having a single mold retooled instead of making multiple molds in different sizes. When shrink rates are significantly different, consider making two molds to ensure the parts are comparable in size.

Figure 2: Molding Shrinkage specifications are listed in the Physical section of material data sheets.

Keep in mind that data sheets are only useful once you know which resins to consider. On the other hand, if you know the characteristics you want but don't know which resins meet those requirements, you can use IDES Properties Search, a fee-based premium service. Properties Search lets you search by more than 500 properties, specifying the ranges you require and narrowing the list of potential resins to a workable number.

If you have questions about reading data sheets, you can contact your Protomold account manager or a customer service engineer at 877.479.3680. They can answer questions regarding properties, but they cannot recommend specific resins. For recommendations on specific resins, a custom compounding specialist like Polyone or RTP should be able to help you. Keep in mind, however, that while outside resources can help with information about resins, no one knows your application as well as you do, so the final choice of resins is yours. The good news is that testing resins in the prototyping phase can help you determine whether you've made the right choice or need to expand your search.

Read past Protomold Design Tips here.

Want more information? Click below.

Published November 2012

Rate this article

View our terms of use and privacy policy